OAK FRAMED BUILDINGS

OUR OAK FRAMED BUILDINGS RANGE

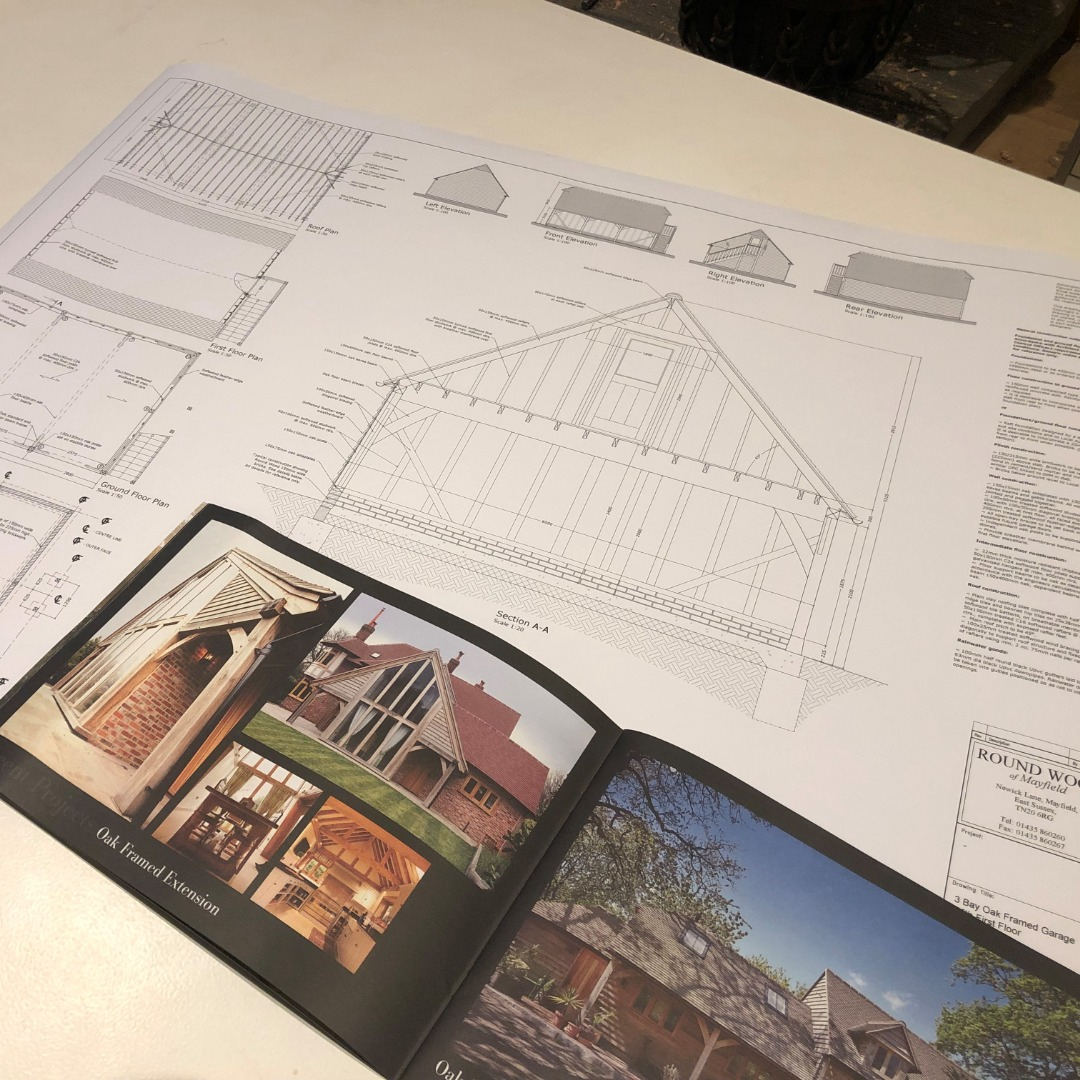

For over thirty years, we have planned, erected and finished thousands of oak framed buildings. These range from porches, garden gazebos and home offices, to large leisure buildings and houses. Unlike others on the market, our frames are fully planed, feature dovetail joints, mortise and tenon joints and curved braces. Regardless of size, every oak frame is approached with the same sense of pride and close attention to detail. All frames are made-to-order and tailored to meet the bespoke requirements of our clients. We typically offer a full service solution through our in-house design and project teams, but are equally happy to simply manufacture and deliver an oak frame if you wish to manage the design and construction elements yourself.

PHOTO GALLERY

PLANNING

Legislation around the construction of a building can be complex and the ultimate responsibility for ensuring your project meets planning and building regulations lies with you.

Specific information relating to planning permission for outbuildings can be found on the planning portal here.

Some of our frames meet planning exemption criteria and may be eligible for construction under permitted development rights. If the site is on what is classed as designated land, which include Areas of Outstanding Natural Beauty (AONB) and conservation areas etc., the permitted development rights vary slightly. It also depends on where you want to put the building within your site, for example, structures in the front garden or near to the boundary, may not qualify and would typically require planning. We recommend you check the latest guidance on the Planning Portal and make a phone call to your local authority to obtain the information required.

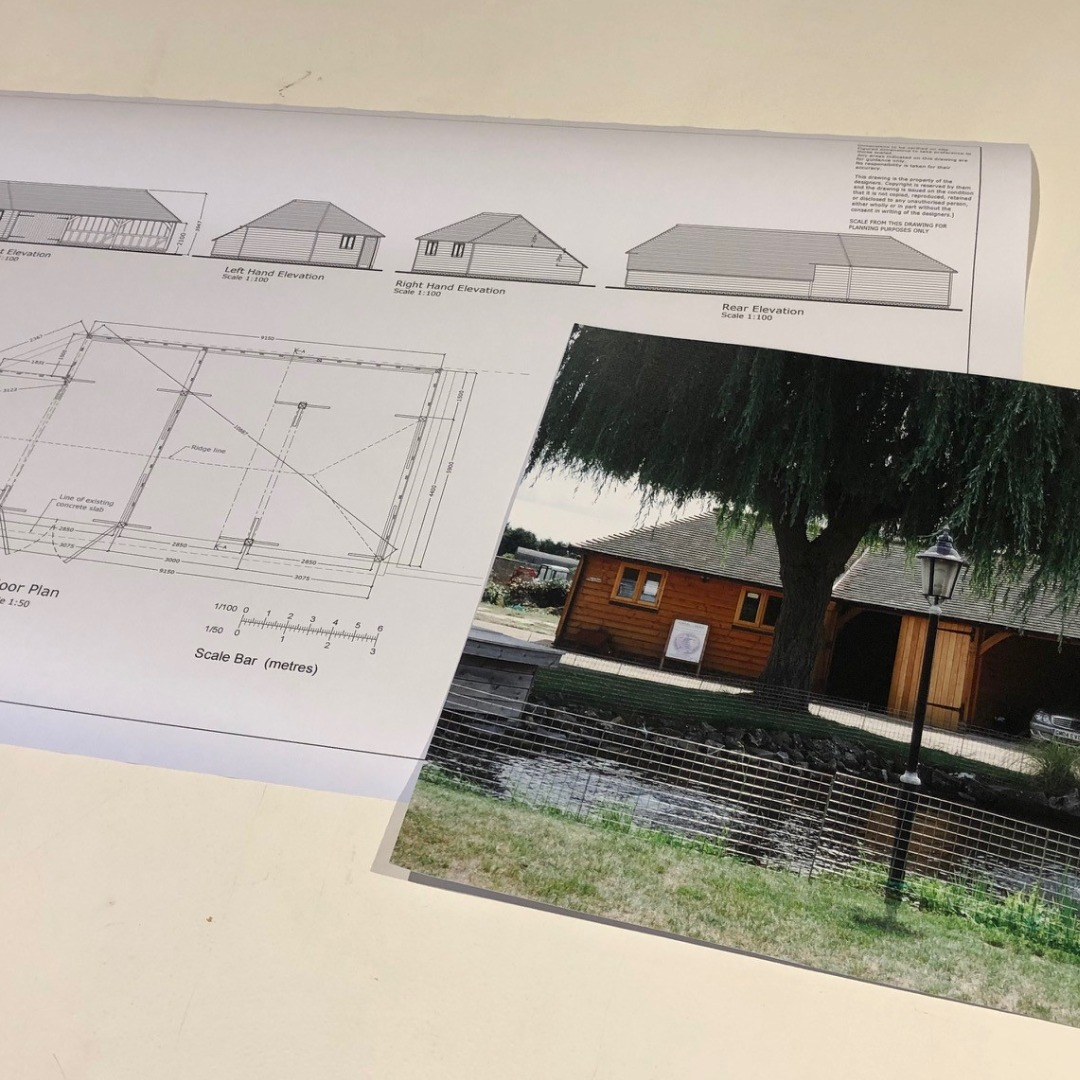

We are able to assist with the Planning Permission process, if required, and can provide Planning Drawings for submission with an application.

BUILDING REGULATIONS

As a guide, building regulation approval is usually required if your building has an internal footprint greater than 30m2 or is less than 1m from a boundary with a floor area greater than 15m2. If the building contains habitable accommodation or has a fixed heating system, approval will be required.

However, regulations are subject to change, so please obtain definitive guidance from your Planning Officer or Building Inspector.

Please contact our team if you require further advice or a full planning service.

RELATED PRODUCTS

GET A QUOTE

Fill out our quick form below and we’ll be in touch shortly about a quote for your dream oak frame building.