HARDWOOD CLADDING

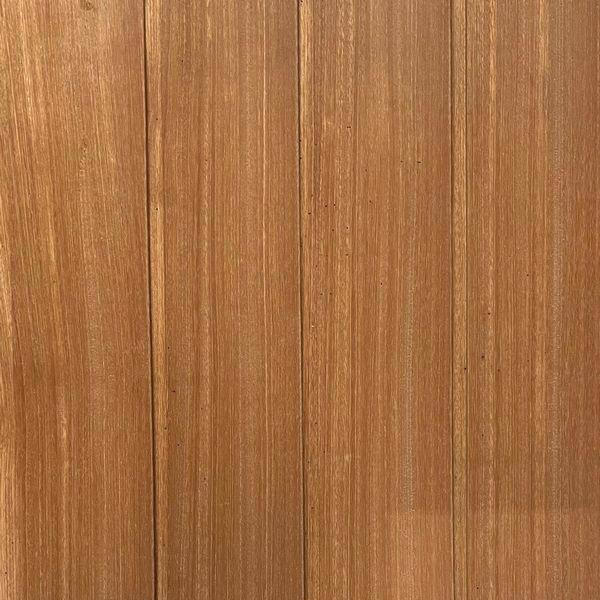

OUR HARDWOOD CLADDING

We specialise in sustainably sourced hardwoods – cut, profiled, and prepared with care in our East Sussex workshop. Whether you're renovating a home or finishing an oak-framed building, our cladding range offers natural beauty, long-term performance, and a choice of distinctive profiles. Browse the range below to find the perfect fit for your project.

Balau shadow gap cladding

£70.83 m2 + VAT (£85.00)

£8.50 m + VAT (£10.20)

Thermory® Benchmark Thermo Ash C6 132mm x 20mm

£78.35 m2 + VAT (£94.02)

£9.56 m + VAT (£11.47)

Thermory® Benchmark Thermo Ash C4J 52mm x 20mm

£93.51 m2 + VAT (£112.21)

£5.33 m + VAT (£6.40)

Oak feather edge cladding

£65.29 m2 + VAT (£78.35)

£9.14 m + VAT (£10.97)

Oak shadow gap cladding

£60.42 m2 + VAT (£72.50)

£7.25 m + VAT (£8.70)

Oak Shingles 10m2 Bag

£840.00 inc VAT

Oak Shingles 1m2 Bundle

£90.00 inc VAT

Oak shiplap cladding

£55.77 m2 + VAT (£66.92)

£7.25 m + VAT (£8.70)

Oak square edge cladding

£65.29 m2 + VAT (£78.35)

£9.14 m + VAT (£10.97)

Ipe shadow gap cladding

£70.67 m2 + VAT (£84.80)

£8.48 m + VAT (£10.17)

Ipe shiplap cladding

£80.50 m2 + VAT (£96.60)

£9.66 m + VAT (£11.59)

Balau shiplap cladding

£70.83 m2 + VAT (£85.00)

£8.50 m + VAT (£10.20)

Cumaru shadow gap cladding

£66.67 m2 + VAT (£80.00)

£8.00 m + VAT (£9.60)

Thermo Treated Bamboo Symphony Cladding

£68.46 m2 + VAT (£82.15)

£8.90 m + VAT (£10.68)

Thermory® Benchmark Thermo Ash C6 155mm x 20mm

£88.28 m2 + VAT (£105.93)

£12.80 m + VAT (£15.36)

Thermory® Benchmark Thermo Ash C23J 150mm x 20mm

£100.91 m2 + VAT (£121.09)

£14.43 m + VAT (£17.32)

Thermory® Benchmark Thermo Ash C4J 52mm x 26mm

£139.30 m2 + VAT (£167.16)

£7.94 m + VAT (£9.53)

Thermory® Benchmark Thermo Ash C7J 72mm x 20mm

£85.72 m2 + VAT (£102.86)

£6.60 m + VAT (£7.92)

Yellow Balau Batten – PAR

£56.60 m2 + VAT (£67.92)

Ipe Batten – PAR

£64.93 m2 + VAT (£77.91)

Why Choose Hardwood Cladding?

Hardwood cladding brings lasting character to any project. Known for its natural resilience, hardwood stands up to the elements with ease. It’s resistant to rot, insects, and weathering, requiring little maintenance beyond the occasional treatment if you wish to preserve its original tones.

We offer only premium hardwoods like oak, ipe, balau and cumaru – each selected for its durability, aesthetic appeal, and long lifespan. These timbers age beautifully, developing a rich, silvery patina over time that many consider a feature, not a flaw.

Profile Styles Explained

Choosing the right hardwood cladding profile is key to achieving your desired aesthetic. We offer a curated range of profiles to suit both traditional and contemporary spaces:

- Featheredge – A classic choice with a tapered cut, designed for overlapping installation. Ideal for rustic or heritage-style buildings.

- Square Edge – Delivers a clean, straightforward look with uniform edges. A timeless option.

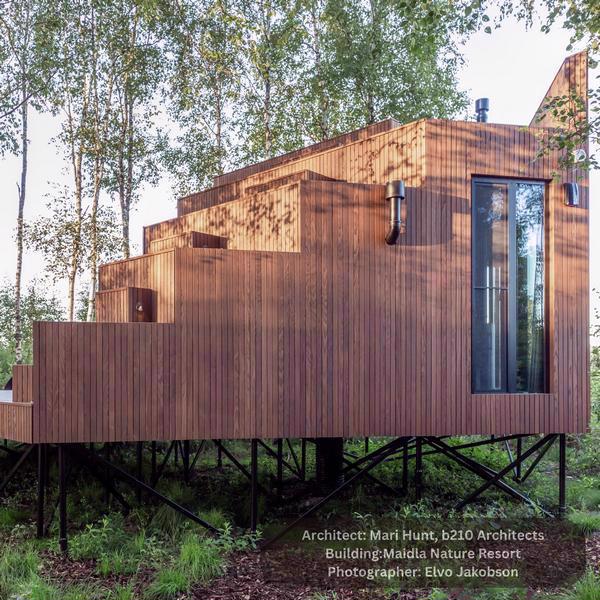

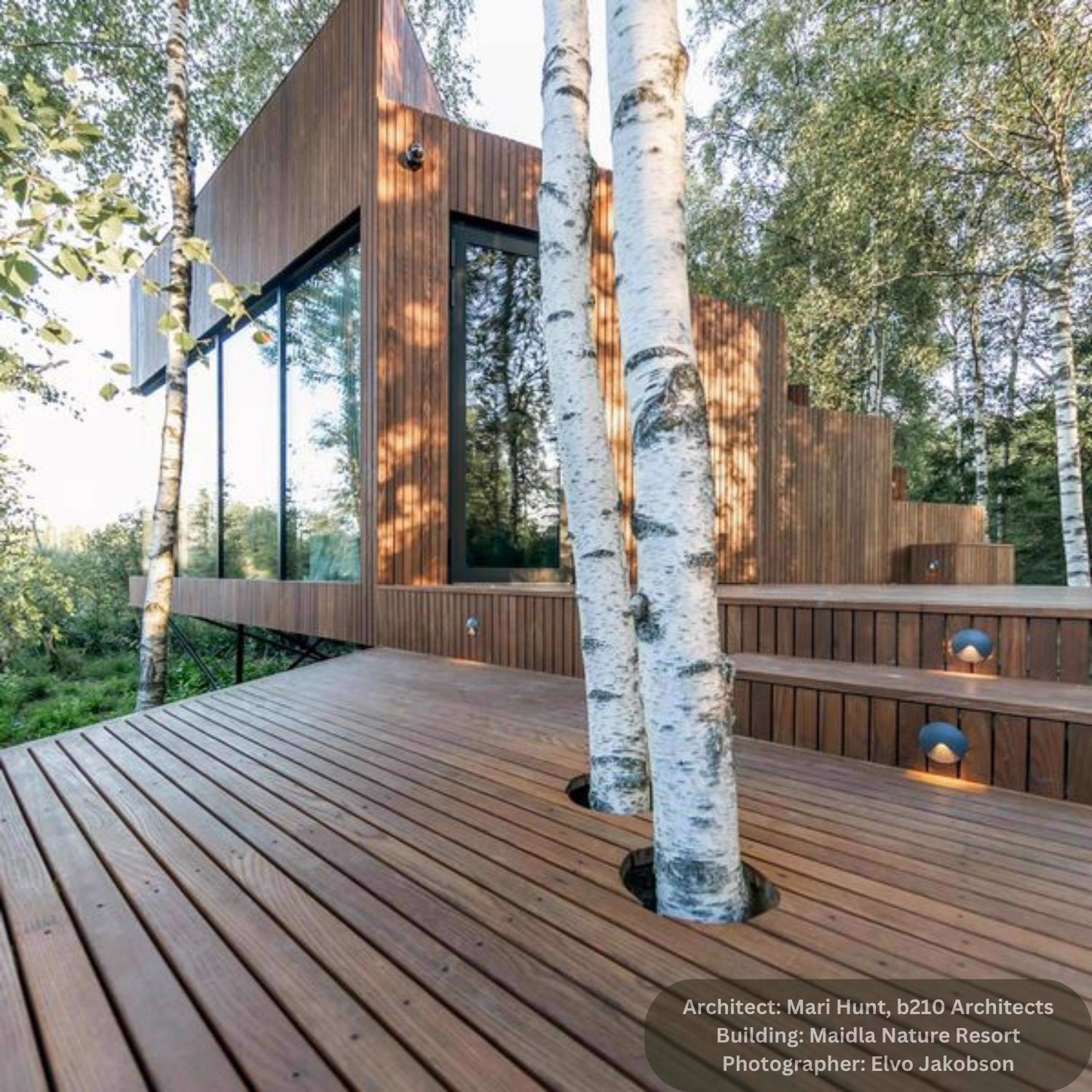

- Shadow Gap – Offers modern definition through a subtle, recessed line between each board. Perfect for staple architectural finishes.

- Shiplap – Boards overlap with a neat channelled effect, balancing a smooth appearance with natural depth.

- Batten – Narrow, evenly spaced slats installed vertically or horizontally. Creates bold visual texture.

- Shingles – Small, individually fitted timber tiles that weather beautifully over time for a naturally aged finish.

Each profile is precision-cut in our Sussex workshop and available across a variety of premium hardwood species.

Hardwood Cladding Installation Advice & Accessories

Getting the best from your hardwood cladding starts with smart installation. We recommend using stainless steel fixings to avoid rust staining and ensure long-term stability. For a clean look, many of our boards are grooved to accept hidden clip systems – ideal for modern facades.

As with all natural timbers, boards will expand and contract slightly with the seasons. Allow a 3–6mm gap between boards, depending on species and width, to accommodate this movement discreetly.

To protect freshly cut ends from moisture ingress, we advise sealing with beeswax or an end grain sealer – a simple step that goes a long way in preserving structural integrity.

Important Note on Sub-Frames

We do not stock softwood for sub-frames. As hardwood specialists, we recommend sourcing sub-frame materials from a standard timber merchant if softwood is required. For best results, install cladding onto a stable and well-ventilated frame, using quality battens and breathable membranes.

Ready to Get Started?

You might know exactly what you need or maybe you require help choosing the right cladding for your build – either way, we’re here to help. Speak to our hardwood team for tailored advice, accurate quantities, and lead time updates.

Call us, request a quote, or browse the full range to start your hardwood cladding project today.

Most of our cladding is available with a lead time of 2–4 weeks, depending on stock and species. If you’re on a tight schedule, contact us and we’ll do our best to meet your timeframe.

Yes – if you’re confident with timber and follow best practices. We provide guidance on spacing, fixings, and finishing. For complex projects, we recommend hiring a professional to provide a reliable finish.

Maintenance is minimal. Leave it to weather naturally or apply UV oil such as Treatex Bangkirai Oil to preserve its colour.

Regular checks are advised – especially after heavy weather. Ensure fixings remain secure, gaps are clear for ventilation, and no moisture is being trapped behind the boards. Freshly cut ends should always be sealed with beeswax or end grain sealer to protect against water ingress.

Our Shadow Gap and Batten profiles are popular for contemporary designs. Both offer clean lines and architectural definition.

Yes! We’re happy to provide small samples to help you assess colour, texture, and finish. Get in touch to request yours today.

Species like Ipe, Balau, and Thermo Ash are particularly suited to harsh climates due to their high density and natural resistance to decay and insects.

Absolutely. Many of our customers use cladding for interior feature walls – especially with Bamboo Symphony or Thermory Ash.

No pre-treatment is necessary unless you wish to apply oil for colour retention. Boards are supplied unfinished, ready for your preferred finish or to be left natural.

GET IN TOUCH

Looking for advice or have a question? You may find the answer in our FAQs here. Alternatively, fill out our quick form below and we’ll put you in touch with the right person in our team! We’ll get back to you by the end of the next working day.